Custom saws

saw for aluminum extrusion and rubber automotive products

Sawing offers advantages over other processes for finishing ends of your product. High surface finish in aluminum for length stability, and smooth surfaces for molding over rubber extrusions.

Products shown here are produced in low volume for processing extrusion for residential and commercial window and door covering products.

machine features

PLC CONTROL : Mitsubishi /Allen-Bradley / AutomationDirect

POSTION CONTROL : Mitsubishi IE Field Network / AB Ethernet IP / Step+Direction direct PLC control

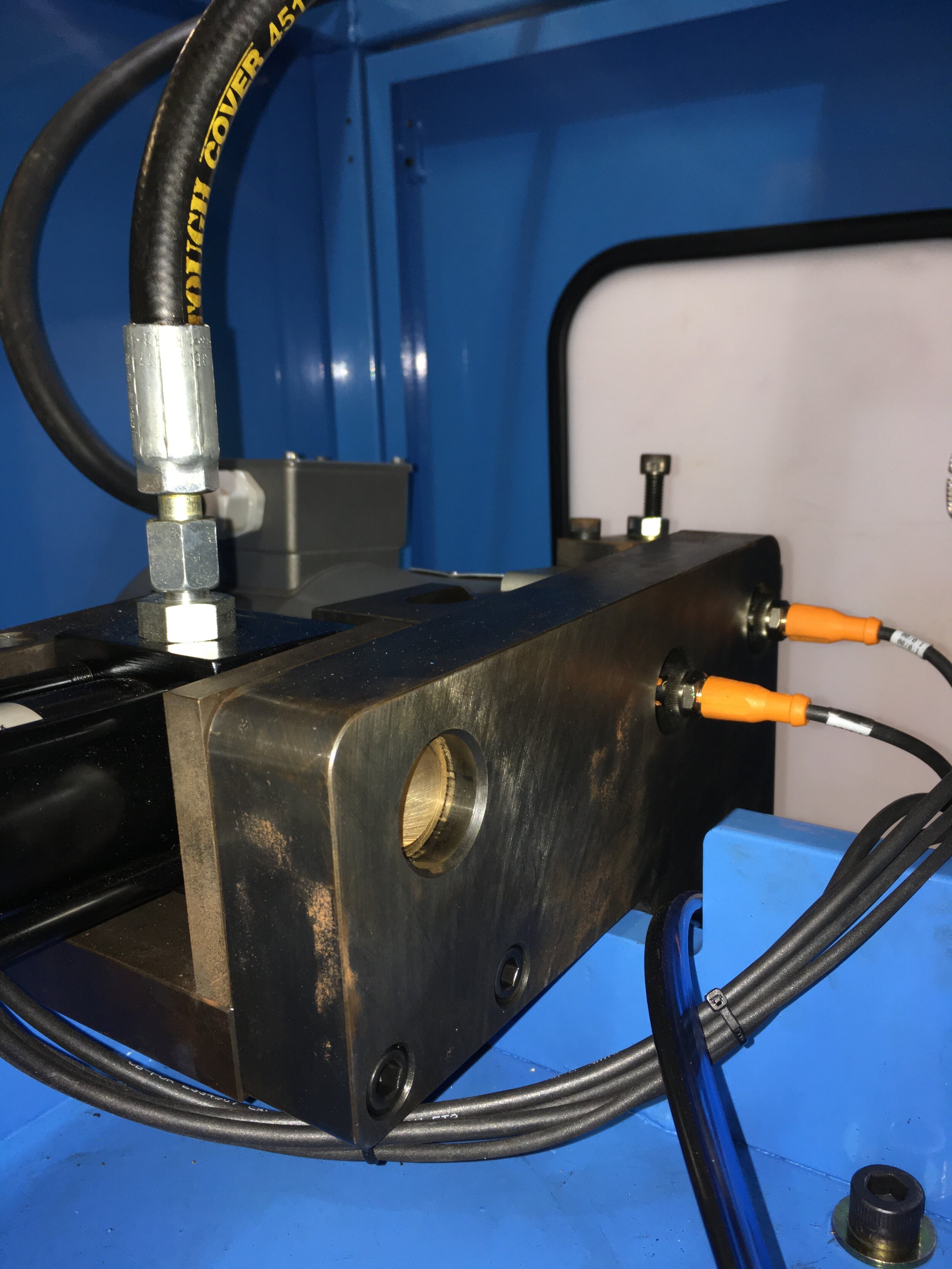

Pneumatics with Hydraulic Rate Controls ( Servo Based solutions available)

Variable Speed Blade Control ( Adjustable via HMI)

Automatic Lubrication

Vacuum connection for chip management or vacuum provided

Multiple Power options available

Full Enclosure of all moving parts.

Safety Features expandable based on degree of operator involvement required

AUTOMOTIVE RUBBER SEALS

Automotive sealing components that require end molding or joining must have a clean square cut for the additional processes to be completed correctly.

These machines use a thin diamond coated abrasive blade. High spindle speeds produce a very light loading of the blade and workpiece so that unsupported features are cut squarely.

All cutting debris is pulled through heat resistant materials trough a wet dust collection system.